How We Make Chocolate

the ARTISAN way

Our Process

The

best beans on earth

get roasted

Nibbed and Winnowed

ground smooth

tempered

Molded & Packaged

Future site of Alberto’s new family home. (cacao farmer in Dominican Republic)

best beans on eartH

It’s a claim not made lightly—claiming to source "The Best Beans on Earth" sets a high bar. Yet, it's a standard we not only aim for but also meet with confidence.

Unlike the vast quantities procured by multinational chocolate corporations—hundreds of thousands of pounds at a time—we have a more discerning approach. Our smaller quantity purchases, jute bags of 100-160 pounds, isn’t just about scale; it's about commitment. This approach enables us to meticulously select the finest beans, pay the deserved premium, and thus, ensure unparalleled quality.

For the mainstream chocolate producer, uniformity trumps quality. Like wine's dependence on grapes, chocolate's essence is drawn from cacao, a product of nature's inherent variability. Many manufacturers sidestep this challenge by relying on cocoa powder (stripped of its cocoa butter), excessive roasting, and intensive processing to guarantee a consistent product year-over-year.

However, the growing artisan, bean-to-bar movement, of which we are a proud participant, heralds a shift. Farmers are increasingly recognizing the value in partnering with chocolate makers who cherish their heritage produce and seek a closer connection (learn more about our farmers). This contrasts sharply with selling lower-grade beans to entities focused solely on mass production of a generic chocolate.

Our quest for cacao is defined by its unique and compelling flavor profiles and preserving its natural integrity every step of the way.

Securing the world's finest beans is just the beginning. The art of roasting is where we carefully nurture their potential without compromising the distinctive flavor profiles we cherish.

Considering the vast diversity of cacao bean varietals, each influenced by its terroir, fermentation methods, and the whims of weather, every batch we receive is unique, often varying from one year to the next. This diversity compels us to meticulously craft a roasting profile tailored to each bean's individual characteristics.

Our focus is sharp on key aspects of the roasting process:

Ambient Conditions: Factors like the starting temperature, humidity, and heat distribution are all taken into account to achieve consistency.

Rate of Rise (RoR): We carefully manage the temperature progression, ensuring each phase of the roast unfolds at an ideal pace for proper flavor development for that bean.

End of Roast (EoR): The final bean temperature, unique to each bean and usually between 240°F to 280°F, is crucial to lock in the flavors developed.

To perfect our approach, we start with a half dozen small batches, each subjected to different roasting profiles. This allows us to pinpoint the optimal process, along with our team of testers, that highlights the bean's inherent qualities, ensuring the final product faithfully represents its origin and essence.

Get Roasted

Once the roasted beans have cooled for at least six hours, we embark on the next critical phase: breaking them into nibs. For this, we repurpose a Champion Juicer, sans filter, a method that also facilitates the separation of the shells, which constitute up to 20% of the total weight. Removing these shells through winnowing is crucial, as they can otherwise mute the chocolate's intricate flavors.

Our winnowing technique is a testament to the ingenuity common among artisan chocolate makers, particularly in the nascent stages of business. We employ a straightforward yet effective method: using a hairdryer set to cool, we gently blow away the lighter shells while stirring the bowl of crushed beans.

Fun Fact: FDA regulations allow finished chocolate to contain up to 2% shell weight. However, our meticulous winnowing efforts ensure our chocolate contains less than 0.5% shell, preserving the purity and intensity of flavor.

Nibbed & Winnowed

Many are surprised to learn that the sole ingredient needed for velvety smooth chocolate is cocoa beans. Despite their dry, hard appearance, nibs possess the potential to become luxuriously smooth chocolate.

The challenge lies in liberating cocoa butter, which makes up about 50% of the bean, from within the bean's cellular structure. Our method involves using a melangeur, where the beans are finely ground between stone wheels and a base. This process not only refines the chocolate but also conches it, mirroring the dual objectives of modern chocolate making.

Within just 15 minutes, the transformation begins to unfold. Yet, we extend the grinding up to 80 hours to achieve a particle size smaller than 20 microns, ensuring an exceptionally smooth mouthfeel.

This prolonged refining step also helps to reduce acidity, a critical step we monitor closely. Somewhere between 2 and 24 hours, once we’ve achieved the ideal balance of acidity, we introduce sugar, which “locks” the current acid levels.

Ground Smooth

For many newcomers to chocolate making, tempering can seem daunting. This step is crucial for controlling the crystallization of cocoa butter, which, without careful management, can set into a form that’s perfectly safe to eat but lacks aesthetic and textural appeal.

At the heart of tempering lies the science of cocoa butter’s polymorphism, which can produce six different types of crystal formations as the chocolate cools. Of these, Type V crystals are the gold standard, giving chocolate its coveted characteristics:

Appearance: glossy, dark, and smooth

Sound: a crisp snap when broken

Feel: gently held without melting and silky smooth once melted in your mouth.

Taste: the fat is a critical flavor carrier.

Fun Fact: Chocolate that has "bloomed"—showing whitish, swirly patterns or splotches—has fallen out of temper. However, it’s entirely safe for consumption. The good news is that bloomed chocolate can be revived to its former glory. By carefully melting and re-tempering, we can guide the cocoa butter back into a Type V dominance, restoring the chocolate’s ideal qualities; nothing lost!

Tempered

Tempering chocolate opens a critical, time-sensitive phase of transferring the smooth, liquid chocolate into molds. This delicate process requires maintaining the perfect temperature to ensure the chocolate sets correctly.

To eliminate air bubbles, ensure the chocolate fills every detail of the mold, and achieve a smooth finish, we tap the filled molds on a surface and use a vibrating table for even distribution.

To prevent the formation of any unwanted crystal types, we wait for the chocolate to develop a matte surface before moving it to a 55°F environment to solidify.

Once set, chocolates are de-molded, with any that don't meet our high standards recycled back into the melting process. Then, we proceed to wrapping and packaging.

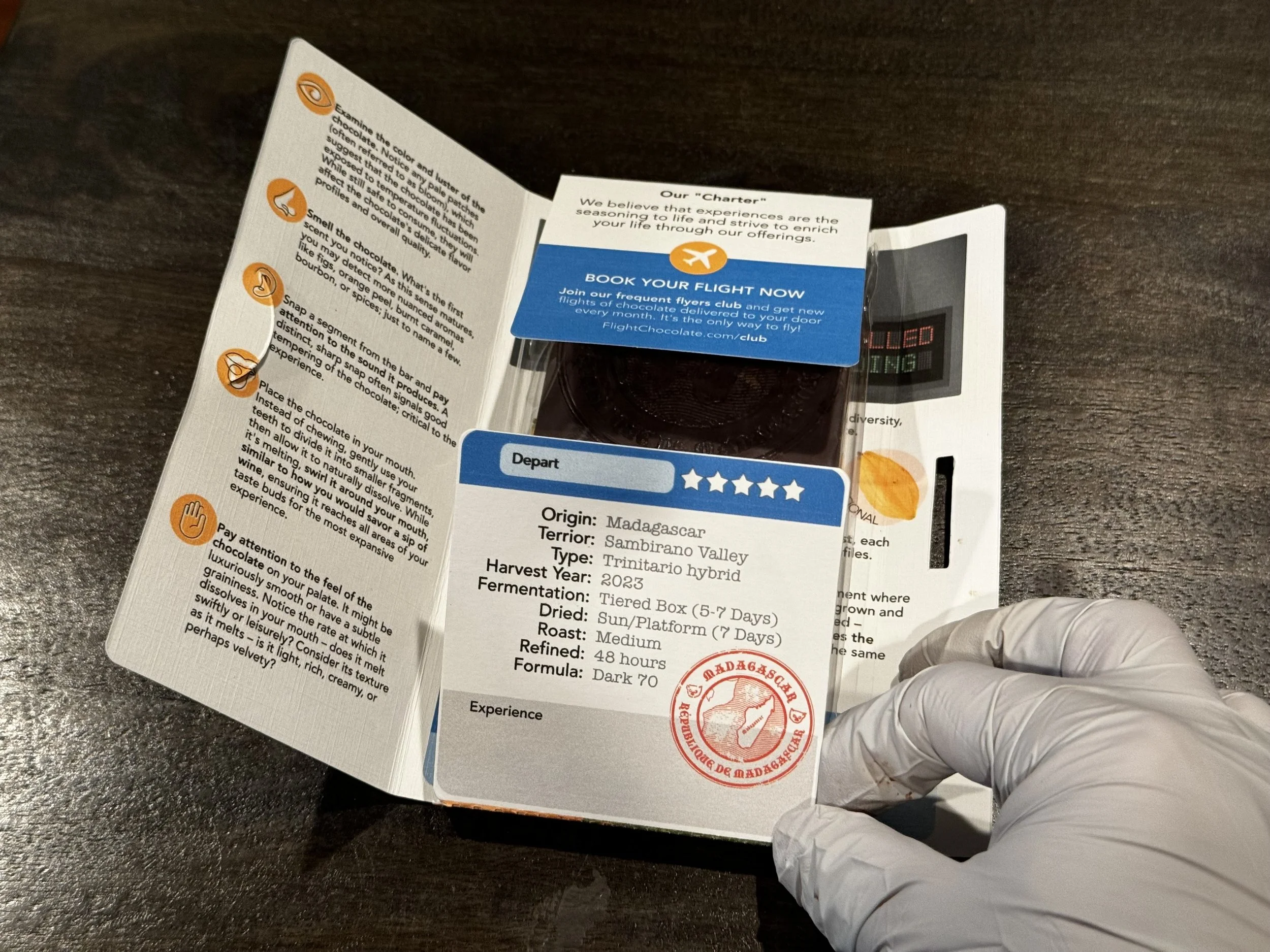

Our packaging is customized for each batch, highlighting the unique traits of the chocolate and including a specific batch identifier, ensuring every piece tells its story.